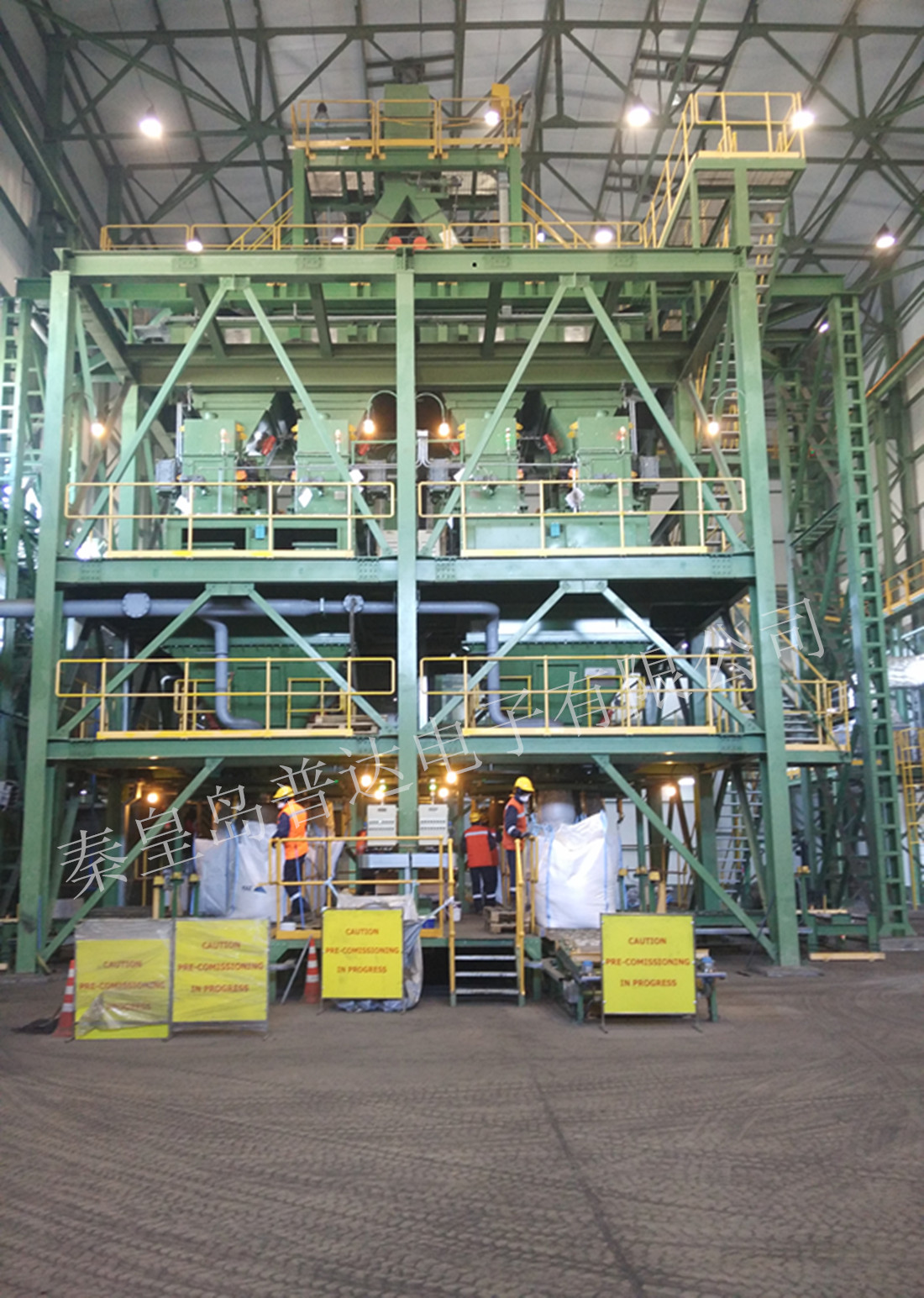

DCS-TWPD Series

500-2000kg/bag

Tel:+86-335 8050535 8050799 8065663

Tel:+86-335 8050535 8050799 8065663  Fax:+86-335 8051760

Fax:+86-335 8051760 Email:puda0335@sohu.com

Email:puda0335@sohu.com

1.Product Description:

This series of machines are designed for packing powdery, muddy, granular, mixture, irregular blocky material into bulk bags and can be designed depending on the requirements of customer. Representative Materials are Starch, Silica, Cement, Dry-mixed Mortar, Titanium Concentrates, Copper Concentrate, Zinc Concentrate, Iron Ore Concentrate, Activated Carbon, Refractory Material, and etc.

2.Technical Parameters:

l Weighing Range: 500-2000 kg

l Packing Rate: 10-40 bags/hour(Packing speed depends on the material features and packing bags)

l Weighing Accuracy:±0.2%

l Applicable Voltage: AC220V-440V 50/60HZ Three-Phase Four-Wire (Client shall provide local voltage class and frequency)

l Air Source Requirement: 0.5-0.8MPa Dry Compressed Air、Total Air Consumption: 0.6m3/min

l Applicable Environment: Altitude≤4300meters (Established Project), Humidity≤95% RH Non-congealable Dew, Operating Temperature:-10℃~50℃, Storage Temperature : -30℃~70℃

3.Working Principle:

The series of machines of DCS-TWPD are designed for big bag via belt feeder. The high precision weighing system can guarantee the accuracy of packaging effectively. Put open bag on the discharging canister, then hang the braces onto the clamping device, start packing machine and clamp the opening automatically. The materials will be delivery to the filling opening through the belt which is controlled by the frequency converters. Filling process is controlled by feed mechanism. Three-level of speed can be chosen: High, Middle and Low. When weight value reaches the preset value, the belt feeder stops working, then loose the bag and braces automatically by the control system. Move the finished bag by forklift or other devices. This kind of machine has the function of bottom vibration, and can adjust the height according to the bag size. It could make the filling materials more compact to increase the capacity of the packing bag. It has the advantages of stable packing speed, high precision weighing, simple operation and easy maintenance, and etc.

4. Specification and Model:

Model | Weighing Range | Fill Rate | Accuracy | Power | Referenced Weight | Referenced Size (m) | Proper Application |

DCS-TWJL Screw | 500-2000kg | 10-30 bags/hour | ±0.2% | 5-11kw | 2500kg | Recommend Mounting Height≥4.2 | Powder |

DCS-TWZL Gravity Flow | 500-2000kg | 20-40 bags/hour | ±0.2% | 4kw | 1500kg | Recommend Mounting Height≥3.3 | Granule |

DCS-TWPD Belt | 500-2000kg | 10-30 bags/hour | ±0.2% | 5kw | 2500kg | Recommend Mounting Height≥4.4 | Powdery and Granular Mixture |

DCS-TWZD Vibration | 500-2000kg | 10-30 bags/hour | ±0.2% | 5kw | 2500kg | Recommend Mounting Height≥4.5 | High Dulk Density and High Hardness Granule |

Complete the form below to get your free quote